How to make Sri Lanka’s anagi II stove

Practical Action

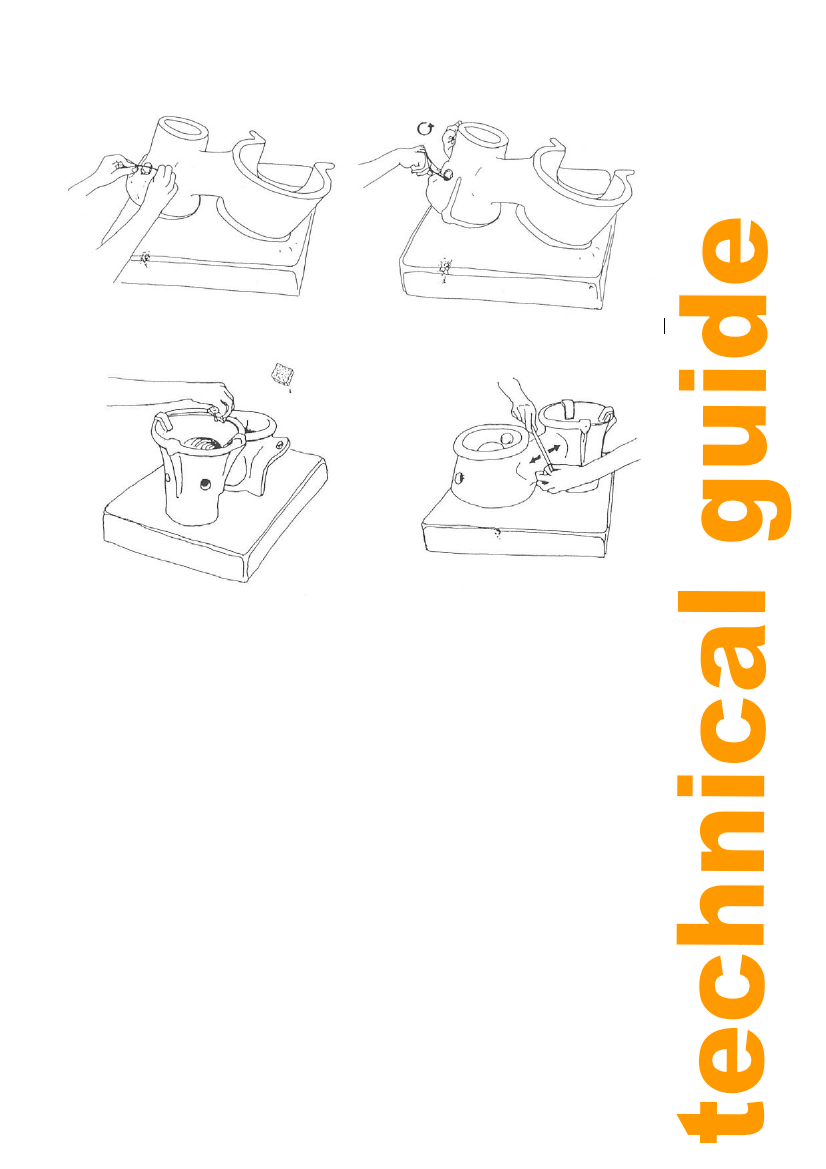

6 & 7.The treatment is given to the second – pothole air holes

8. Any other rough areas are rubbed with a

sponge

9. and then with the stick to give a hard, shiny

surface.

Drying and Firing

After the final finishing, the stoves may be left to dry on racks or in a storage shed without

the special pallet. The stoves should dry indoors, protected from sun, wind, excessive heat,

and especially rain. Slow, even drying is necessary to prevent warpage.

The time required to dry stoves thoroughly is approximately 2 weeks. This will vary in the wet

and dry seasons. In dry seasons, care must be taken to prevent the stoves from drying too

fast. In wet seasons, care must be taken to see that the stoves dry thoroughly before firing.

The stoves should be checked for cracks before being placed in the kiln. This can be done by

one of the assemblers. If a stove has cracks, it should not be fired but returned to the clay

pile. Any cracks in the stove will get significantly bigger in firing.

Likely causes of cracking while drying include drying too quickly and unevenly and by joining

pieces which are too dry with clay that is more wet.. Once such production problems are

solved, it is rare for any cracks to occur during drying.

The stoves may be fired in traditional pottery kilns or in tile factory kilns. In the tile factories,

stoves are fired on top of the layers of tiles, in space that is often unused. A maximum of 3

layers of stoves may be fired; more than 3 and the bottom layer of stoves will crack from the

excess weight during the stress of firing. Up to 150 stoves can be safely fired in each kiln

load. This is the output of one team (1potter and 4 assemblers) in one week, and the firing

cycle is one week. Therefore, a tile factory can fire the products of as many stove teams as it

has kilns, without extra cost.

28